Where

Innovation

Meets

Longevity

- Distributors / Dealership

Enquiries Solicited: 9767000085 - Distributors / Dealership

Enquiries Solicited: 9767000085 - Distributors / Dealership

Enquiries Solicited: 9767000085 - Distributors / Dealership

Enquiries Solicited: 9767000085 - Distributors / Dealership

Enquiries Solicited: 9767000085

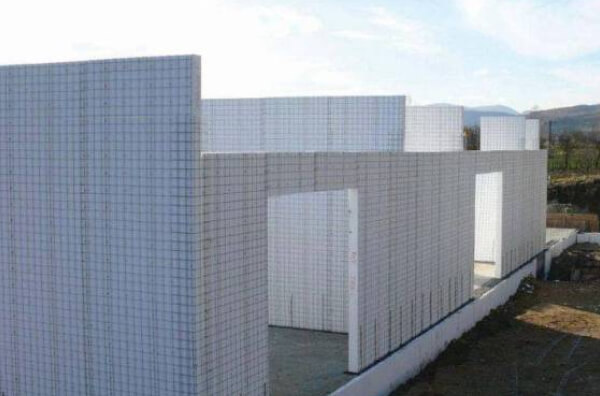

North India’s leading Eps panel manufacturers

The most trusted alternative to

conventional brick masonry

Superior Strength

Despite being lightweight, EPS Panel’s distinctive structure offers the advantages of exceptional rigidity and compressive strength.

Cost-effective

EPS Panels outperform traditional materials while costing substantially less. The quick construction saves money significantly.

10x faster

Construction Pace

EPS panels are easy to cut and don’t need expensive machinery. It takes roughly a month to complete the rough construction of a 100 m2 house.

Thermal, Fire &

Moisture Resistant

EPS Panels have high thermal and fire resistance and don’t degrade even when subjected to prolonged soaking in water.

Lightweight & Easy to Transport

Owing to their lightweight and sturdy properties, EPS Panels are easy to handle and carry, even under the most unfavorable conditions.

Good acoustic performance

EPS Panels absorb sound, both impact sound in floating floors and airborne sound for walls.

USAGE

Applications

Due to their long lasting durability, thermal resistance and lightweight nature, EPS Panels are extensively used as a modern day structural solution.

Airport

Kitchen

Garage

Basement

Residences

Residences

Hospital

Warehouse

Mall

Restaurant

School

Hospital

Schedule a visit

Ongoing Projects

eps panels

Building a

sustainable future

As an eco-friendly building material, EPS Panels offer substantial environmental advantages over other forms of insulation. At no point during its production or use, airborne fibers or chlorofluorocarbons (CFCs or HCFCs) are produced.

Best of all, EPS Panels do not generate any waste. All leftover or defective material is recycled back into the manufacturing process and repurposed.

Client Showcase

Our Esteemed Clients

frequently asked questions

FAQs

Our team has compiled a list of the most commonly asked questions about EPS Panels. We hope this helps!

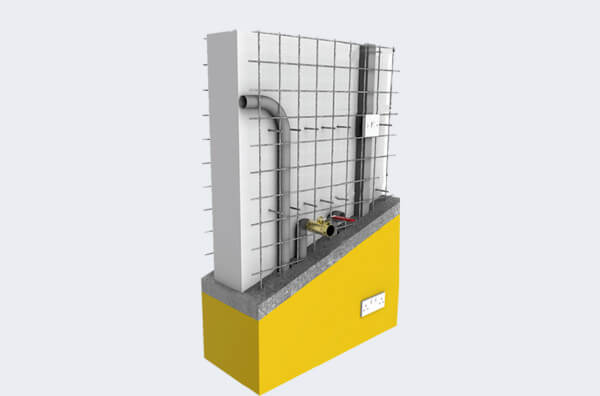

What is the EPS Panels Construction Method?

The EPPS, or Expanded Polystyrene Panel System, is an industrialised system of modular panels that enables quicker assembly than traditional systems. It performs the necessary load-bearing and structural duties, has high thermal and acoustic resistance, and a variety of shapes and finishes to allow diversity in the design compaction process.

How EPS Panels are better than traditional construction method?

EPS panels are a better alternative to traditional building processes. These insulated panels are sturdy, long-lasting, easy to maintain, move, and are entirely recyclable. The most significant advantage is the cost savings, which include both construction and material costs.

What is the product specification of EPS Panel?

EPS Panels are available in the following sizes:

Width: 1200 mm

Length: 2000 ~ 6000 mm

EPS Slab Thickness: 50, 80, 100, 120, 150 mm

EPS Slab Type: Plain or Corrugated

Mesh Spacing: 50 x 50 mm, 100 x 100 mm

Mesh Wire Thickness (dia): 2.5 mm, 2.0 mm, 3.0 mm

What is the technical specification of EPS Panel?

Wall Panel (2.5mm Wire, 50x50mm Mesh, 50mm EPS Panel + 1” plaster both sides)

Self Load: 120 kg/m2

Load Bearing: 350 KN/m

Plaster Ratio: 1% Coat 15mm of 1:2:3 (chips mix — 100% of size < 6mm)

2d Coat 10mm of 1:5 (Cement/Sand only)

Roof Panel (2.5mm Wire, 50x50mm Mesh, 80mm EPS Panel + 1” plaster + 3” concrete)

Self Load: 580 kg/m2

Load Bearing: 10 KN/m

Concrete Ratio: 1:2:4 (Chips mix – 50% of size < 18mm + 50% of size < 10mm)

https://youtu.be/q5wB5YPkpekhttps://youtu.be/-KYff07GYR4

We’d love to hear from you

Contact Us

Incase of any queries or questions, get in touch with us right away. Our team will be happy to assist you.

[contact-form-7 id=”209″ title=”Contact form 1″]